How Can Custom Hydraulic Systems Improve Operational Efficiency?

Release Time :

2026-01-01

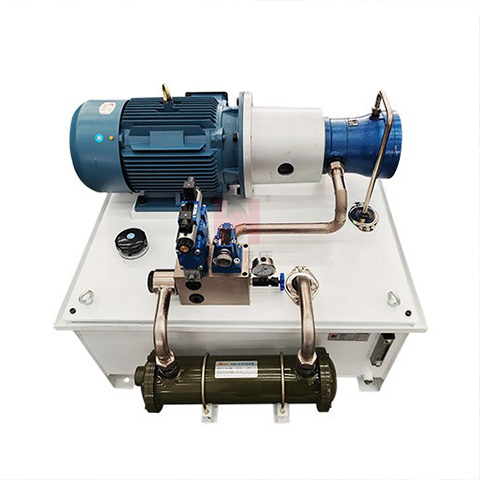

Hydraulic systems are widely used in construction machinery, industrial equipment, mining, agriculture, and many other fields. While standard hydraulic systems can meet general requirements, they are not always the most efficient solution for specific applications. This is where custom hydraulic systems come into play. By tailoring the system to real operating conditions, companies can significantly improve operational efficiency, reliability, and overall performance.

So how exactly do custom hydraulic systems make a difference? Let’s take a closer look.

1. Matching the System to Real Working Conditions

One of the biggest advantages of custom hydraulic systems is that they are designed around actual operating needs, not assumptions.

Standard systems are built to cover a wide range of applications, which often leads to compromises:

Oversized components

Unnecessary energy consumption

Inefficient control response

A custom system, on the other hand, is engineered based on:

Load requirements

Working pressure and flow

Duty cycles

Environmental conditions

In simple terms, the system does what it needs to do—no more, no less. This avoids wasted power and helps the machine work smarter, not harder.

2. Improved Energy Efficiency and Lower Power Loss

Energy loss is a common issue in poorly matched hydraulic systems. Custom hydraulic designs can reduce losses by:

Selecting pumps with the right displacement and efficiency range

Optimizing valve configuration and flow paths

Minimizing pressure drops in pipelines

These improvements lead to smoother operation and reduced heat generation. Less heat means less energy wasted, and also less stress on hydraulic oil and components. It’s one of those behind-the-scenes improvements that quietly saves money over time.

3. Faster and More Accurate System Response

Operational efficiency is not just about power—it’s also about control.

Custom hydraulic systems can integrate:

Proportional or servo valves

Load-sensing or pressure-compensated circuits

Application-specific control logic

This allows the system to respond more quickly and accurately to operator input. Whether it’s lifting, drilling, clamping, or steering, precise control reduces cycle time and improves productivity. And honestly, operators usually notice this right away—it just feels better to use.

4. Better Component Integration and System Layout

A custom hydraulic system is designed as a whole, not as a collection of separate parts. This improves efficiency by:

Reducing unnecessary hoses and fittings

Improving space utilization

Simplifying system structure

A cleaner layout means fewer potential leakage points and easier troubleshooting. When everything is arranged logically, maintenance becomes less time-consuming, which indirectly boosts operational efficiency as well.

5. Increased Reliability and Reduced Downtime

Efficiency drops sharply when equipment is down for repairs. Custom hydraulic systems improve reliability by:

Selecting components rated for actual loads instead of theoretical limits

Designing circuits that reduce shock and pressure spikes

Improving oil cleanliness management

By reducing unexpected failures, equipment stays in service longer and maintenance schedules become more predictable. In real-world operations, fewer surprises usually mean better efficiency.

6. Adaptability for Future Upgrades or Process Changes

Another often overlooked benefit is flexibility. Custom hydraulic systems can be designed with future expansion or modification in mind, such as:

Reserved control ports

Modular valve blocks

Upgrade-ready control interfaces

This makes it easier to adapt the equipment when production requirements change. Instead of replacing the entire system, targeted adjustments can be made—saving both time and cost.

7. Optimized Maintenance and Operating Costs

While custom systems are not about unrealistic cost savings, they do help optimize long-term operating expenses by:

Reducing oil degradation due to excess heat

Extending component service life

Simplifying maintenance procedures

Over time, these practical benefits add up. The system runs more efficiently, maintenance becomes more manageable, and overall operating costs stay under control.

Conclusion

Custom hydraulic systems improve operational efficiency by aligning system design with real-world requirements. Through better energy use, faster response, improved reliability, and smarter integration, they help equipment perform more consistently and productively.

It’s not about chasing perfection or making bold claims—it’s about practical engineering choices that fit the application. When a hydraulic system is designed to match the job, efficiency tends to follow naturally.

RELATED NEWS

2026-01-15

How Are Hydraulic Cylinders Used in Metallurgical Electric Furnaces?

Metallurgical electric furnaces play a crucial role in modern steelmaking and non-ferrous metal smelting processes. These furnaces operate under extreme conditions, including high temperatures, heavy mechanical loads, and continuous operati···

2026-01-15

How Does Our Hydraulic Cylinder Enhance Metallurgical Electric Furnace Control?

In metallurgical electric furnace systems—such as electric arc furnaces (EAF), submerged arc furnaces, and resistance furnaces—precise mechanical control plays a critical role in ensuring stable operation, energy efficiency, and equipment···

2026-01-08

What Drives Demand for Welded High-Pressure Cylinders?

Welded high-pressure cylinders play a critical role in the storage and transportation of compressed gases across multiple industries. Unlike seamless cylinders, welded cylinders are manufactured by forming and welding steel components, allo···

2026-01-08

How Do We Ensure Durability in High-Pressure Welded Cylinders?

High-pressure welded cylinders are widely used in industries such as energy, chemical processing, medical gases, and industrial manufacturing. Because these cylinders often operate under extreme internal pressure and harsh environments, dur···

2026-01-01

What Role Do Hydraulic Systems Play in Automation?

Automation has become a key driver of efficiency and consistency in modern industry. From manufacturing and material handling to construction and energy sectors, automated systems are designed to reduce manual intervention while improving a···

2026-01-01

How Can Custom Hydraulic Systems Improve Operational Efficiency?

Hydraulic systems are widely used in construction machinery, industrial equipment, mining, agriculture, and many other fields. While standard hydraulic systems can meet general requirements, they are not always the most efficient solution f···

GET YOUR FREE QUOTE

We will contact you within 24 hours. ( WhatsApp/facebook:13665121168)